10 Best Leather Laser Engraving Machine 2025 in the United States

Winner

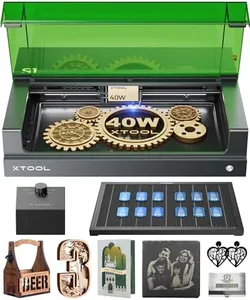

xTool S1 40W Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-Friendly, Laser Engravering Machine for Wood and Metal, Acrylic, etc. - Basic Bundle

The xTool S1 40W Laser Engraver and Cutter Machine is an impressive option for those looking to delve into laser engraving, particularly in materials like leather. With a robust 40W laser power, it can effortlessly cut through thick materials, making it suitable for a range of projects. Its large engraving area of 23.93" x 15.16" allows for sizable items, while speeds of up to 600mm/s enhance productivity, appealing to both hobbyists and small business owners alike.

Most important from

193 reviews

xTool P2 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, Curved Surface Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather (White)

The xTool P2 55W CO2 Laser Cutter is a robust option for those looking to engage in leather laser engraving and other materials. A key strength of this machine is its powerful 55W laser tube, which allows for efficient cutting through various materials, including leather, wood, and acrylic. This makes it suitable for both professional and hobbyist creators. The large engraving area of 26" x 14" coupled with a notable speed of up to 600mm/s enhances its capability, allowing for quicker project completion without sacrificing quality.

Most important from

60 reviews

CREALITY FALCON2 22W Laser Engraver Machine with Air Assist and Rotary Roller, 220W High Accuracy Laser Engraver and Cutter Machine for Cylindrical Objects, 25000mm/min Faster Engraving

The CREALITY FALCON2 22W Laser Engraver Machine is a powerful tool for leather and other materials, boasting a high laser power of 22W. This means it can cut through thicker materials, such as 15mm wood or 10mm black acrylic, in a single pass, making it ideal for various crafting and small business needs. Its impressive engraving speed of 25,000mm/min allows for quick and efficient production, which is great for batch work or customized gifts. The machine's resolution and precision are top-notch, ensuring detailed and accurate engravings.

Most important from

80 reviews

Top 10 Best Leather Laser Engraving Machine 2025 in the United States

Winner

9.9 score

xTool S1 40W Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-Friendly, Laser Engravering Machine for Wood and Metal, Acrylic, etc. - Basic Bundle

xTool S1 40W Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-Friendly, Laser Engravering Machine for Wood and Metal, Acrylic, etc. - Basic Bundle

Chosen by 1258 this week

xTool P2 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, Curved Surface Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather (White)

xTool P2 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, Curved Surface Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather (White)

CREALITY FALCON2 22W Laser Engraver Machine with Air Assist and Rotary Roller, 220W High Accuracy Laser Engraver and Cutter Machine for Cylindrical Objects, 25000mm/min Faster Engraving

CREALITY FALCON2 22W Laser Engraver Machine with Air Assist and Rotary Roller, 220W High Accuracy Laser Engraver and Cutter Machine for Cylindrical Objects, 25000mm/min Faster Engraving

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, Ultra HD Fiber Laser Engraver for Jewelry, Metal, Wood, Leather

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, Ultra HD Fiber Laser Engraver for Jewelry, Metal, Wood, Leather

LaserPecker LP4 Laser Engraver Ultimate Bundle with Air Purifier, Slide and Rotary Extension, Dual Laser Engraving and Cutting Machine for Metal, Wood, Acylic, Jewelry etc.

LaserPecker LP4 Laser Engraver Ultimate Bundle with Air Purifier, Slide and Rotary Extension, Dual Laser Engraving and Cutting Machine for Metal, Wood, Acylic, Jewelry etc.

LaserPecker LP5 20W Fiber & Diode Dual Laser Engraver, 10X Faster 0.0027mm Precision for Metal/Wood/Jewelry, Portable 6kg Laser Cutter for Instant Store Customization, 3D Grayscale Engraving Machine

LaserPecker LP5 20W Fiber & Diode Dual Laser Engraver, 10X Faster 0.0027mm Precision for Metal/Wood/Jewelry, Portable 6kg Laser Cutter for Instant Store Customization, 3D Grayscale Engraving Machine

WECREAT Vision 40W Laser Engraver and Cutter Machine with Automatic Conveyor Feeder, Fume Extractor, 4-in-1 Rotary, Air Assist, Laser Bed for DIY Engraving and Cutting Acrylic Wood Metal Leather

WECREAT Vision 40W Laser Engraver and Cutter Machine with Automatic Conveyor Feeder, Fume Extractor, 4-in-1 Rotary, Air Assist, Laser Bed for DIY Engraving and Cutting Acrylic Wood Metal Leather

LaserPecker LP2 Laser Engraver with Roller, Portable and Handheld Laser Engraving Machine for Wood Metal Leather Acylic Engraving Laser Cutter, Suit Set with Versatile Rotary Roller

LaserPecker LP2 Laser Engraver with Roller, Portable and Handheld Laser Engraving Machine for Wood Metal Leather Acylic Engraving Laser Cutter, Suit Set with Versatile Rotary Roller

8.6 score

WECREAT Vista 10W Laser Engraver with 9-in 1 Rotary, Compact Diode Desktop Laser Engraving Machine with Smart HD Camera for Beginners DIY Hobbyist Wood Leather Acrylic Vinyl Jewelry Gifts Making

WECREAT Vista 10W Laser Engraver with 9-in 1 Rotary, Compact Diode Desktop Laser Engraving Machine with Smart HD Camera for Beginners DIY Hobbyist Wood Leather Acrylic Vinyl Jewelry Gifts Making

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.